|

|

|

|

|

| |

|

|

| |

In a solar photovoltaic (PV) power system, solar panels and inverters work together to collect solar energy and convert it into usable electricity. While solar panels have become commodity products, inverters remain a key energy harvest component that has attracted a lot of attention and investment. |

|

| |

|

|

| |

|

|

| |

Central Inverter or String Inverter |

|

| |

|

|

| |

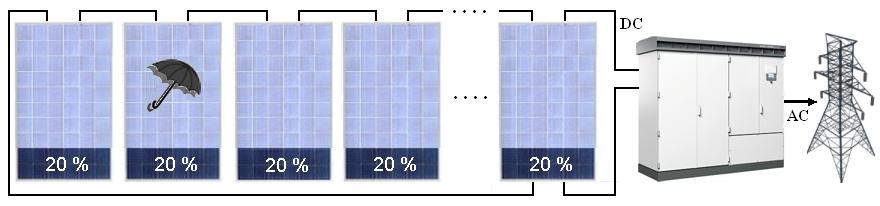

In a traditional solar power system, the DC output from each solar panel is combined in a DC junction box. The final DC output from the DC junction box is connected to a large central DC-AC power inverter to generate electricity.

Using a Central (or String) Inverter includes the following shortcomings:

1. If the inverter fails, the entire solar power system is down;

2. The performance of the entire solar power system is dictated by the performance of the weakest solar panel. Therefore, power production is negatively affected by non-uniformity of solar panels, sunlight variations or partial shading due to clouds, trees, dust on the panel. As shown in the following graphic, even if only one solar panel is partially shaded, the entire system performance will drop significantly. |

|

| |

|

|

| |

|

|

| |

|

|

| |

3. The Maximum Power Point Tracking (MPPT) can only be applied to a system level, not to each solar panel;

4. A lot of design and installation effort must be made to assure the solar panels are properly oriented in respect to each other;

5. DC wiring from each solar panel to the junction box can be costly and labor intensive; and

6. High-voltage DC such as 600V is distributed in the system and has the potential to trigger a high intensity arc, which can cause fire. This is a major issue for installing a central inverter based solar power system on the roof of a commercial building. |

|

| |

|

|

| |

|

|

| |

Microinverter |

|

| |

|

|

| |

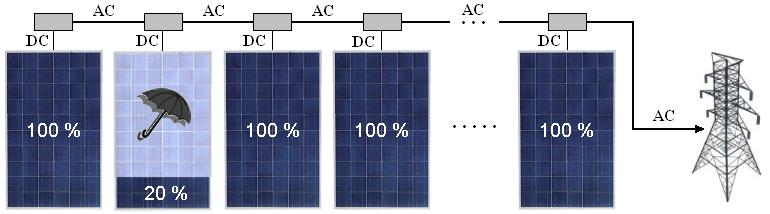

A solar power Microinverter typically has a compact and moisture proof design so that it can be attached directly to a solar panel. Microinverters overcome the shortcomings of Central Inverters in many ways.

1. Maximum Power Point Tracking (MPPT) can be performed for each panel so that solar power production is improved by 10% to 15%.

2. Microinverters can sharply reduce the installation cost because no more detailed solar alignment design is required, and DC wiring to DC junction box is no longer needed.

3. There is no high-voltage or high-current DC in a solar power system using Microinverters. So, it is much safer for the installer, user, and the property.

4. No more partial shading problems. As shown in the following graphic, if a solar panel is partially shaded, it will not affect the performance of other panels. |

|

| |

|

|

| |

|

|

| |

|

|

| |

Microinverters, however, have their own set of challenges including the following:

1. While a Central Inverter is typically installed on a wall or on the ground out of direct sunlight, a Microinverter is typically attached to the solar panel on the roof top, which can be a very harsh environment.

2. Since the enclosure of a Microinverter must be sealed to be water proof, cooling fans cannot be used. Therefore, a Microinverter has to be designed and manufactured to generate minimal heat.

3. Since each solar panel requires one Microinverter, the per watt cost for a Microinverter based solar power system is higher than a Central Inverter based system. As an example, the inverter cost in a solar power system is about $0.50 per watt for Central Inverters versus $0.80 - $1.00 per watt for Microinverters. Although a Microinverter based system has long term benefits, the higher entry cost can discourage buyers. |

|

| |

|

|

| |

|

|

| |

Mini-Inverter |

|

| |

|

|

| |

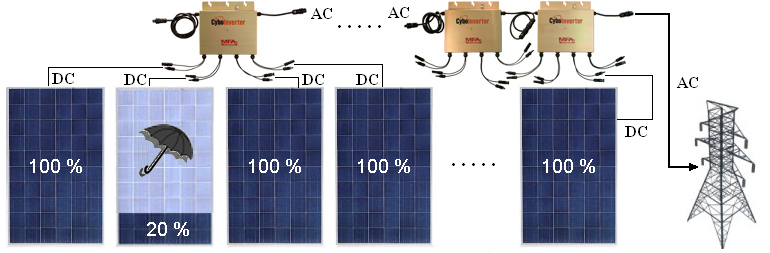

The patent pending CyboInverter is the world’s first Mini-Inverter that possesses the key merits of both Central Inverters and Microinverters. What is more, a CyboInverter overcomes the main shortcomings of both Central Inverters and Microinverters with the following key features and benefits:

1. A CyboInverter has multiple input channels to connect to multiple solar panels so that the inverter’s per watt cost can be further reduced.

2. A CyboInverter can connect to multiple solar panels that may be different in types, sizes, and sunlight orientations.

3. A CyboInverter can perform Maximum Power Point Tracking (MPPT) on each connected solar panel to optimize power production.

4. No more partial shading problems. As shown in the following graphic, when a solar panel is partially shaded, it will not affect the performance of other panels. |

|

| |

|

|

| |

|

|

| |

|

|

| |

5. A number of CyboInverters that connect to a mixed number and variety of solar panels can easily daisy chain with standard AC power cables and connectors. The total generated power equals to the summation of the AC power supplied by each CyboInverter.

6. CyboInverters can cut down the installation cost tremendously because no more detailed solar alignment design is required, and DC wiring to DC junction box is no longer needed. What is more, a CyboInverter can typically replace 4 Microinverters so that it further reduces the installation work.

7. The inputs to a CyboInverter are low-voltage DC and the output from the CyboInverter is the standard 240V AC, so there is no high-voltage or high-current DC in the system. It is much safer for the installer, user, and the property.

8. CyboInverters offer grid-flexibility with both Grid-tie and Off-grid CyboInverters in the same product family. |

|

| |

|

|

|